Comparisons Of PU Products

Polyurethanes have definite advantages over plastics, conventional rubber and metals, which make them a better substitute in applications where these materials are normally used.

… vs. Rubber

- high abrasion resistance

- high cut, tear resistance

- superior load bearing

- thick section molding

- colorability

- oil resistance

- ozone resistance

- radiation resistance

- broader hardness range

- castable nature

- low pressure tooling

… vs. Metal

- lightweight

- noise reduction

- abrasion resistance

- less expensive fabrication

- corrosion resistance

- resilience

- impact resistance

- flexibility

- easily moldable

- non-conductive

- non-sparking

… vs. Plastic

- high impact resistance

- elastic memory

- abrasion resistance

- noise reduction

- variable coefficient of friction

- resilience

- thick section molding

- lower cost tooling

- low temperature resistance

- cold flow resistance

- radiation resistance

Some specific properties of Polyurethanes when examined show it to be a more practical choice as compared to those of rubber, metal and plastic.

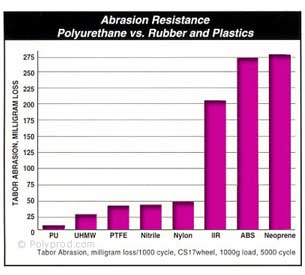

Abrasion Resistance:

The outstanding abrasion resistance of Cast polyurethanes has resulted in thousands of successful applications. In laboratory tests as well as in field applications, Cast Polyurethanes show a definite wear advantage over many other materials, The following figure illustrates a comparison of abrasion properties of Polyurethane with rubbers and plastics.

Right side figure illustrates a comparison of abrasion properties of solid polyurethane with rubbers and plastics. In field studies, polyurethanes have outworn rubbers and plastics, as well as steel and ceramics in some applications, by a factor of 8 to 1.

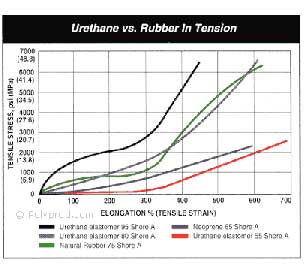

Stress /Strain Properties

Some plastics have high modulus and tensile strength but low elongation. Most rubbers , have high elongation but low modulus and tensile strength. Polyurethane elastomers have high modulus, high tensile strength and high elongation. This combination imparts toughness and durability to the part.

Left side figure compares the stress/strain properties of some polyurethanes with those of a few rubber materials.

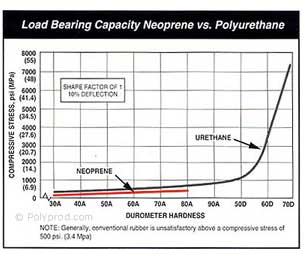

Compression Properties:

Cast Polyurethanes have much higher load-bearing capacity than conventional elastomers of similar hardness.

Right side figure is a comparison of the compressive stresses required to cause a 10% deflection with samples of cast polyurethanes and Neoprene rubber. This high load bearing capacity , combined with the superior abrasion and toughness is an important advantage in applications like metal forming die-pads, die springs, Fork lift tires, caster wheels, industrial rolls, etc.

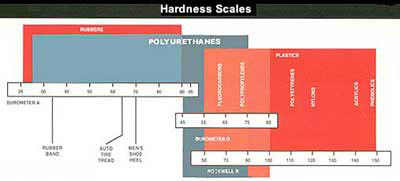

Hardness and Resilience:

Cast Polyurethane elastomers can be compounded in a wide range of hardness from 20A to 75D (soft as a rubber band or as hard as plastic) Special formulations of cast polyurethanes can be made with resilience values as low as 2% or 75%. This is ideal for applications such as springs and shock mounts.

Products

- Rotary & General Sealing

- O Rings

- V Rings

- Hydraulic Rod Seals

- Wiper Seal

- Hydraulic Others

- Pneumatic Seals

- Pneumatic Rod Seals

- Piston Seals

- Rubber Sheets

- Expansion Joints & Bellows

- Fabric Bellows

- Gaskets

- Rubber Plastic & PVC Caps

- Engineering Plastic

- General Products

- Custom Made Rubber

- PTFE Products

- Pu Products

- Diaphragms

Technical Data

© Mech Spares Pvt. Ltd. All rights reserved.

Website Design by EWEBAC